CTW takes many calls and more e-mails on what machine is the best for motorcycle fork and damper testing. We tried to answer all the questions with a PDF explanation.

Introduction to Motorcycle Testing and Equipment

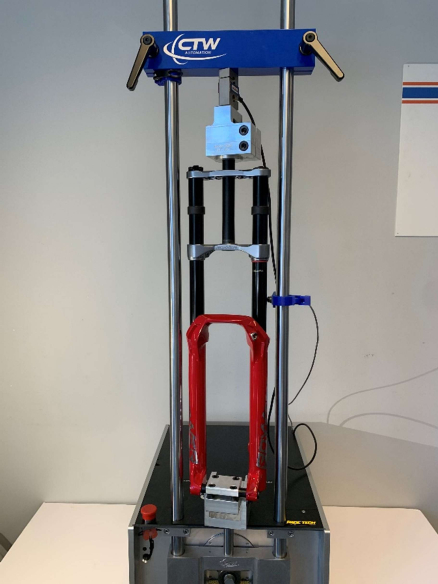

For motorcycle testing, we sell several machines. It always comes down to the customer’s budget. I will detail as much information as I can and send pictures of forks in the machine.

First, we need to understand if this is a motorcycle for the street, a track circuit that is smooth (GP) or what is called moto-cross (on dirt, lots of jumps) here in the USA. Each of these involve a front fork but they see very different velocities in the fork.

ctwautomation-blog-motorcycle_testing-1

GP Race bike - smooth track/circuit

ctwautomation-blog-motorcycle_testing-2

Motocross - dirt, rough, jumps

- Motorcycle front forks, on the bike, will see very high compression velocities. The highest are from Motocross where they jump in the air and land very hard. The front forks can see more than 8.0 M/sec and the rear damper can see more than 3 M/sec in compression. The rear damper also has a very poor motion ratio so it sees less movement for a given wheel travel.

- The extension / rebound for the front and rear see much less velocity than the compression and this is very important. If you try to run the read damper at high extension velocities it would potentially fail and/or break. The wheel simply cannot extend very fast in the real world compared to how quickly it will comrpess. This is more severe on the rear damper where forces are high.

- Even though the front fork will have a total travel ability of 300+mm, you do not need to test at full travel. You simply find a good stroke to test and repeat on every fork.

The RD7.5 is the best crank dyno for motorcycle testing. It has a peak stroke of 160mm for the front fork and can test at up to 3.00 M/sec on that stroke. It is a very good value for how much testing you can do.

You can use the smaller strokes for the rear damper as well. The RD10 is just a little bit better because it has more horsepower (HP) so it can compress / extend a damper with higher forces.

The one thing that a “crank dyno” cannot do is run a different compression and extension velocity. On the motorcycle, the compression will always go faster than the rebound / extension side. The only way to do this is with a linear actuator.

The linear actuator can be programmed to run faster and faster on compression while keeping the extension speed at the same, lower velocity. A test profile will be different from a crank-type machine (RD3 / RD7.5 / RD10) compared to the LA series.

Examples …

Sample Test Profile of crank type machine – 150 mm stroke example – front fork – Sine wave input

| Compression Velocity | Extension Velocity | |

|---|---|---|

| 1 | 0.250 M/sec | 0.250 M/sec |

| 2 | 0.500 M/sec | 0.500 M/sec |

| 3 | 0.750 M/sec | 0.750 M/sec |

| 4 | 1.000 M/sec | 1.000 M/sec |

| 5 | 1.500 M/sec | 1.500 M/sec |

| 6 | 2.000 M/sec | 2.000 M/sec |

| 7 | 2.500 M/sec | 2.500 M/sec |

Sample Test Profile of linear actuator – Variable Velocity – Variable sine wave input

| Compression Velocity | Extension Velocity | |

|---|---|---|

| 1 | 0.250 M/sec | 0.250 M/sec |

| 2 | 0.500 M/sec | 0.500 M/sec |

| 3 | 0.750 M/sec | 0.750 M/sec |

| 4 | 1.000 M/sec | 1.000 M/sec |

| 5 | 1.500 M/sec | 1.500 M/sec |

| 6 | 2.000 M/sec | 1.500 M/sec |

| 7 | 2.500 M/sec | 1.500 M/sec |

| 8 | 3.000 M/sec | 1.500 M/sec |

| 9 | 3.500 M/sec | 1.500 M/sec |

| 10 | 4.000 M/sec | 1.500 M/sec |

| 11 | 5.000 M/sec | 1.500 M/sec |

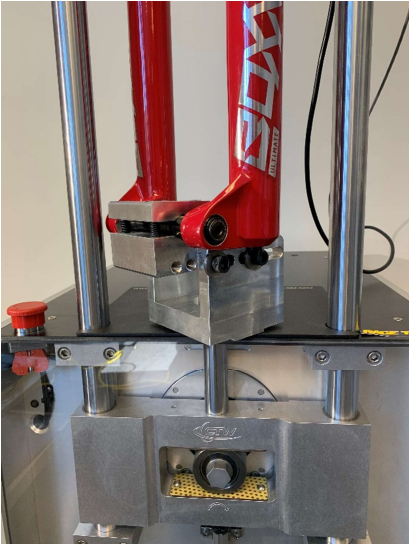

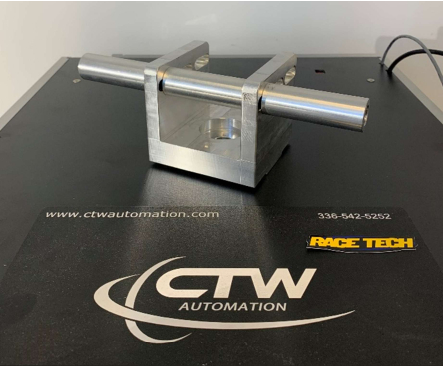

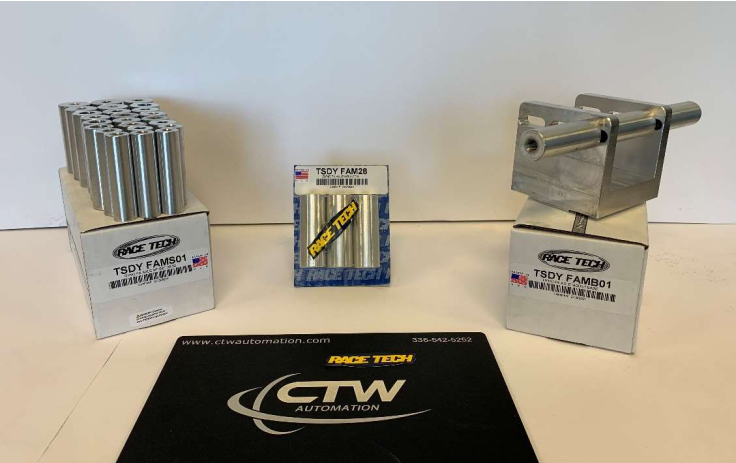

Testing / Fixtures for the dyno

These come from Race Tech and we happily sell and provide them to our customers.

You can run an individual cartridge, a total front fork assembly and the rear damper using various fixtures for the machine.