2024 December

Current version of CTW Probe© software 24.6.14.1918 (next release Jan 2025)

CTW Automation year in review with 2025 preview

In 2024, CTW sold and produced 75 new damper and spring testing machines. At the same time, we also converted roughly 100 Roehrig Engineering shock dynos and EMA’s to operate on our CTW Probe© software. Overall, since our inception in 2016, we have produced 600 machines and taken over the service and support of about 500 Roehrig Engineering machines, worldwide.

The RD3, RD7.5 and the LA410 continue to be our best sellers.

We produced (3) new versions of our recently copyrighted software, Probe©. Each one brought forward new features and additions as well as the typical fixes and updates required by Windows changes. We will continue this progress for the coming year with updates being released on a 4-month time frame. Our release schedule of software updates and feature additions will continue to introduce many important features that will help to expand CTW’s market reach. We also have begun to think and plan about the next major update likely to be seen in 2026 that would take Probe© to the next level.

In 2024, CTW brought several new products to the market.

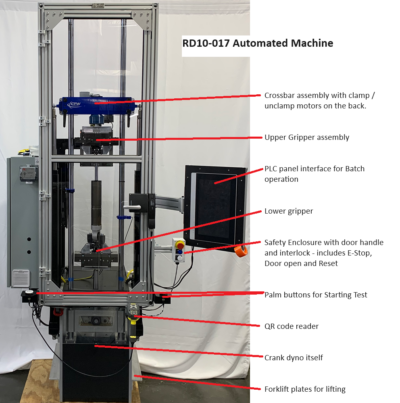

The Automated RD. CTW produced and installed a fully automated RD10 into Thailand. This machine starts with a QR code reader that allows for saved test procedures to be executed based on the specifics of the damper.

Automated grippers that can be interchanged based on the damper end / eye.

Automated crossbar movement to a desired preload, based on QR code.

Automated crossbar clamp / unclamp.

Full enclosure / cage protection.

Palm activated start mechanism for safety.

Database generation that automatically updates after each test.

Pass / Fail validation of the specimen including a lock out if the damper fails.

Cycle times are based on Tests parameters but very able to do a rod force and 3 speeds in 45 to 55 seconds.

Fully Automated RD Series

The second “automated” machine we produced this year is a one-button test. Installed into Indonesia at an OEM supplier, this RD5 with a one-button Test was called the NAGARA switch.

User creates a test, a Validation and a Naming sequence to begin. These would all use a similar naming convention to identify a damper model.

User manually loads the damper

Presses the button and the Test runs, auto-saves the data, adds a line to the *.csv database and gives the results on the screen for Pass or Fail.

These machines and software allow CTW to offer a full line of Validation and Automation to fit almost any production requirement.

1-button / NAGARA switch RD series

Shown with CE cage and simple User interface for operation

CTW produced and delivered our fist HIL (hardware in the loop) capable machine. Using our LA series, we developed an interface that allows for HIL testing. The machine can be used in this manner or as a normal LA and allows for a quick and easy. CTW notes that we simply give the ability to exchange the displacement signal in real time. The customer provides the software to create the feedback.

CTW developed custom wave form analog outputs to drive valves / solenoids for use in the next generation of dampers coming to market. While we also have had discrete voltage output, analog out, this feature allows for a User defined varied output to drive up to (4) valves at one time. This is the beginning of the CDC valve control testing platform. Our Users will be able to define the response of the valve(s) in real time.

CTW Probe© has also added a durability command that will provide a future expansion into simple durability testing. While in its first stages, the promise can be seen and used currently. We are finishing (Q1 2025) our first multi-station durability machine, and we will continue to expand in this market. We understand the world is fixed on hydraulic rigs, but in many cases these can be replaced by a much simpler system that uses less space, less energy and far cleaner to the environment.

Now for 2025!!

New motion controller – CTW is working on a long list of new machines, added functionality and software features coming to market for our current and future customers. The biggest will be an all-new controller from Aerotech. The A1 will replace the A3200 hardware and firmware in the LA series of machines. CTW will begin shipping new machines with this controller in Q1 of 2025. We have been beta testing for the last 6 months and Aerotech has been very helpful in meeting our requirements. This new controller will use the BA-100 servo amplifiers that have been used in the Roehrig EMA systems for 20 years with high success. This new development will also allow CTW and its partners to better service and update existing Roehrig EMA’s in the field to a modern Win10/11 platform.

New Damper Dyno for the Motorcycle and Mountain Bike market – We are in the final design stages of producing what we call the RD5 long stroke machine. This machine fills a void that CTW currently has when trying to compete against our competition. The RD5 is a great machine but only has a 50mm peak stroke. The RD7.5 is a long stroke machine (160mm) but it is large and more expensive than other market choices. By using the running gear of the RD5 and the crank head of the RD7.5, CTW will produce a RD5 Motorcycle Dyno able to run a front fork well over 2.0 M/sec on a large stroke. We will begin advertising and taking deposits with the goal to produce the first machine in Q2 of 2025.

New LA Model for Low Noise (dB) testing – We have finished the engineering phase of what will become the CTW Low Noise machine. By using our already very quiet LA series, our initial testing shows that we should be able to work in a 40 dB environment that will allow the user to “listen” to the damper. With the market of EV vehicles, a quiet damper is as important as a well handling damper. With this series of machines, we aim to give the User the ability to develop the audible components of the damper as well as the performance characteristics. We have a great background from our work at Roehrig to allow us to move forward quickly into this arena.

New Ability / Feature – We are working to make our SR17 actuator for spring and elastomer testing into a computer-controlled actuator. It currently requires the user to move the actuator using a hand held pendant. This will become a well-priced electric linear actuator with automated testing to drive the spring using a constant velocity motion in each direction. Our current machine far exceeds our competitors in stiffness, accuracy, and repeatability and now we will drive it from the CTW Probe© software interface. From there, we imagine installing larger actuators to move further into the spring testing world.

Dyno Research Additions – We are working to add a 2- and 4-unit pressure harness to the crank dynos as an option. All CTW crank type machines, and most of the Roehrig machines we service, have additional channels that are free to use. We are working to provide a kit to allow the User to install and collect pressure signals so they can better understand what is happening in their dampers.

We hope this all finds you well and excited for what is yet to come.

Worldwide Dealers for CTW Products

Australia –

Performance Wholesale Australia

6 Cronulla Court

Slacks Creek, QLD 4127

Ph: +61 7 38081986

Email: sales@pwa-au.com.au

Website: https://www.performancewholesale.com.au/

Queensland Speedway Spares

2 Cronulla Court

Slacks Creek, QLD 4127

Ph: +61 7 38084333

Email: qss@pwa-qss.com

Website: https://www.speedwayspares.com.au/

Japan –

Enable-apg

224-1 Haneo, Odawara, Kanagawa 256-0804

Contact sales: Shingo Sobu

Ph: +81-465-46-7408

Email: info@enable-apg.jp

Website: https://www.enable-apg.jp/

China –

Shenzhen Lynag Technology Co., Ltd

地址:深圳市龙岗区横岗社区富康路92号A栋110

Ph: +86-0755-28507276

Email: info@lynag.com

Website: www.lynag.com

India –

Tii Techno Testing Instruments Pvt. Ltd.

403, Mariegold Building, Neco Gardens

Viman Nagar, Pune 411014, India

web: www.ti-india.com

email: ram@ti-india.com

All CTW Automation products come with:

* 1-year warranty

* 1-year Support contract that allows the owner to have unlimited phone, e-mail, and TeamViewer remote access so that CTW can make sure you have the answers to questions quickly and easily. These can also be purchased by current Roehrig dyno owners as we can help with those as well.

Places to find CTW Automation….

Website: www.CTWAutomation.com

Facebook: fb – CTW Automation

Facebook CTW Group: CTW Automation – Shock and Damper Dyno Group

- For the advanced user and common questions

YouTube: CTW YouTube

- Home for training videos

- Demonstrations and teaching

Instagram: ctw_automation

Sales: sales@ctwautomation.com

Support: support@ctwautomation.com